We moved into my Granddad's house this past summer and among some of the things that came with the house was some of his parents belongings. One night my youngest son was quizzing me about combines and somehow the conversation turned towards combines without cabs. This brought a very curios look to his face. I remembered seeing a box marked photos, expecting to find photos from the 1950's to show him pictures of cabless combines. I was quite surprised to find pictures this old. I'm also very thankful that they took the time to label many of the pictures with the people in them, what they were doing and the year. Some of these pictures have made it on my

twitter feed on throwback Thursdays. As always these photos along with lots that haven't made it on the blog yet are on my

Flickr account.

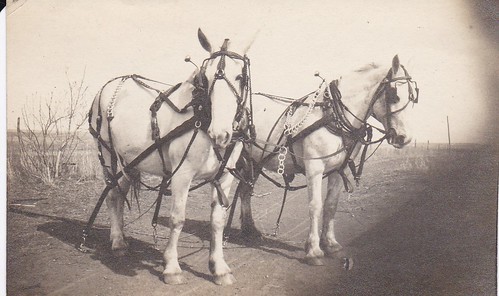

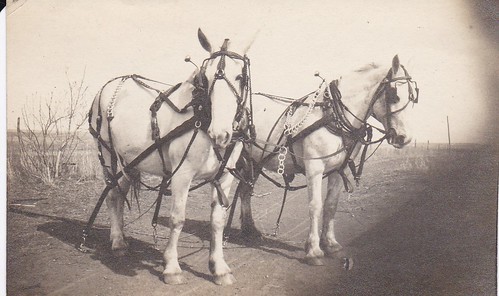

Maude and Nell, 1912. It's not wrote on the photo, but I assume that is my great granddad in the photo.

Maude and Nell again in 1912, new harness.

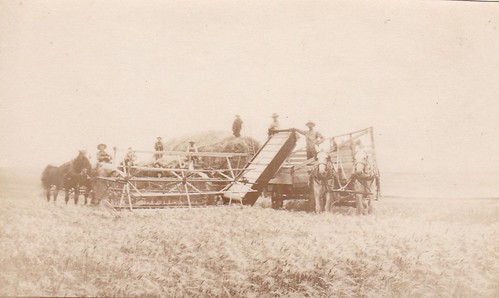

No year, but the people are labeled. 1 R. T. Tibbits, my great granddad, 2. H.R. Tibbits, my great-great grandfather, 3 Miller, I presume either hired help or neighbor that they traded labor with.

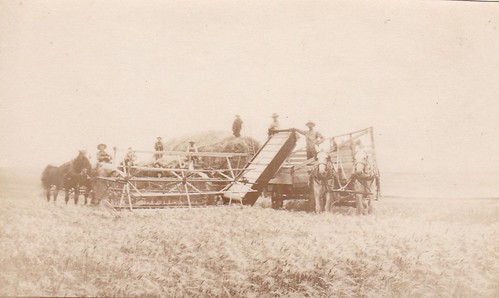

No names or dates were on this picture. It appears that it took quite a crew to harvest.

Stacking bundle grain, no date.

1. Fred Schur, the Schur family are long time neighbors, 2. George Tibbits, I think it is great-great granddads brother, 3. Herbert or H.R. Tibbits, great-great granddad.

No names or dates.

Mabel Tibbits, my great grandma, 1923. It also has August 1923 wrote in pencil on the back of the picture, which is the month and year my granddad was born.

All that is wrote on the picture is 1929. It looks like they were harvesting some really nice wheat that year.

Fred Cline at the combine wheel, Riley T. sitting on the grain tank, Herbert standing on the truck, and Riley D. sitting on the truck bed. Three generations in the field, Herbert is my great-great granddad, Riley T. is my great granddad, and Riley D. is my granddad.

Fred Cline on the tractor, Riley D. on the ground, Riley T. at the combine's wheel, and Herbert standing on the platform.

Cy Austin, 1929. I don't remember how he is related to us, but it is a really good picture of the combine working.

No name or date wrote down,

Cutting Atlas, 1941. Atlas was a predecessor to forage sorghum, I think they would take it back to the farm and chop it as silage and blow it into an upright silo to feed during the winter.

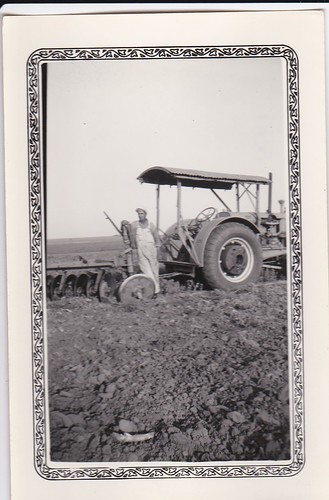

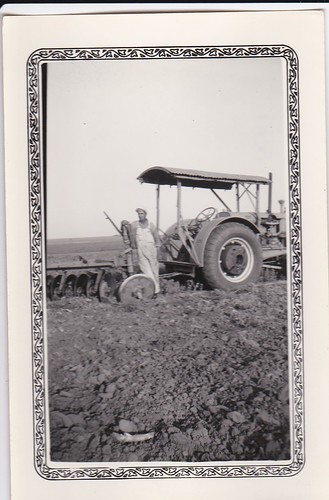

Riley T,, 1936. I think he might be cutting Atlas or corn.

Farmall cultivating, 1936. Either Atlas or corn. Looks like the leaves might be curled some which can be cause by heat or drought stress.

Listing corn, 1934. A lister pushes dirt out of the way and seed is planted in the bottom of the furrow, then the ridges will be knocked down when they cultivated.

1935, It looks like they are listing I would guess corn.

Herbert, drilling wheat 1936. He is using 2 12 hole and a 16 hole drill.

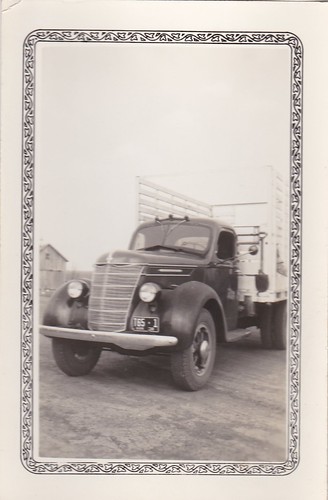

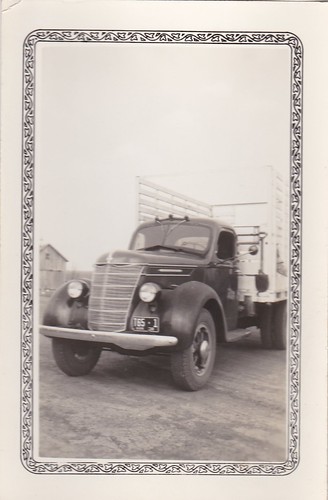

1937 D35 truck. The back of the picture says 1947, but the tag is a 38. The truck is gone, but the tag might be part of a collection.

Pet heifers,1936.

These are all of the pictures I have scanned so far. There are more farm pictures from this time frame in the box.

I was looking through them thinking how neat it was to have them and then it struck me that many of them were from the Great Depression and dust bowl era. With that in mind some of these pictures will resurface along with some of the others in future blogs.